Introduction

Commercial hydroponic systems have revolutionized the way we grow crops, offering a sustainable and efficient alternative to traditional soil-based agriculture. These systems allow for precise control over nutrient delivery, water usage, and environmental conditions, resulting in higher yields and better quality produce. As the demand for fresh, locally grown food continues to rise, choosing the right hydroponic system has become crucial for maximizing yield and ensuring long-term success. In this comprehensive guide, I will explore the top commercial hydroponic systems for 2024, each designed to cater to different crop types, space requirements, and budgets.

From the classic Nutrient Film Technique (NFT) to the cutting-edge aeroponics systems, we’ll delve into the intricacies of each method, highlighting their advantages, disadvantages, and top recommendations. However, before diving into the specifics, it’s essential to understand the problem at hand: With so many hydroponic systems available on the market, selecting the most suitable one for your commercial operation can be a daunting task.

This introduction aims to provide an overview of the various options, equipping you with the knowledge to make an informed decision that aligns with your goals and maximizes your yield potential.

Overview of Commercial Hydroponic Systems and Their Benefits

Commercial hydroponic systems have surged in popularity, offering a groundbreaking alternative to conventional soil-based farming. These systems, which grow crops in a nutrient-enriched water solution instead of soil, directly deliver vital minerals and nutrients to plant roots. A standout advantage of commercial hydroponic systems is their efficient use of space. By employing vertical or stacked growing arrangements, they can dramatically boost yield per square foot, making them perfect for urban farming and regions with scarce land.

Moreover, hydroponic systems grant meticulous control over environmental variables like temperature, humidity, and light, facilitating the ideal conditions for diverse crop cultivation. Another key benefit is water conservation; these systems recirculate the nutrient solution, significantly cutting down on water waste and lessening their environmental footprint. They also negate the need for soil tilling, slashing labor costs, and averting soil erosion.

Pest and disease control is markedly improved in hydroponic setups due to the controlled environment and lack of soil, which reduces the incidence of soil-borne diseases and pests. This not only elevates crop quality but also diminishes the reliance on pesticides, championing sustainable and environmentally friendly farming methods. With their capacity to elevate yields, save resources, and ensure consistent produce quality, commercial hydroponic systems are transforming agriculture, presenting a sustainable answer to the escalating demand for fresh, locally sourced food.

Importance of Choosing the Right System for Maximizing Yield

The selection of an optimal commercial hydroponic system is pivotal for enhancing crop yield and securing the sustainability of your agricultural venture. Each hydroponic system presents distinct features, advantages, and constraints, necessitating a thorough assessment of your specific needs and objectives. An ideal hydroponic system will maximize the efficiency of resources like water and nutrients and create the perfect conditions for your crops to thrive. This leads to not only an increase in yield but also an enhancement in crop quality, which can boost profitability and provide a competitive advantage.

Moreover, the hydroponic system you choose should be in harmony with your space constraints, financial plan, and the level of automation you desire. Some systems might demand a higher upfront cost but can lead to greater scalability and reduced long-term operational expenses. Conversely, other systems might be more appropriate for smaller operations. By meticulously analyzing factors such as the type of crops, their growth cycles, and the maintenance they require, you can identify a hydroponic system that promotes efficiency, reduces waste, and delivers consistent, high-quality yields. Making an informed choice in this regard is essential for the success of a sustainable and profitable commercial hydroponic enterprise.

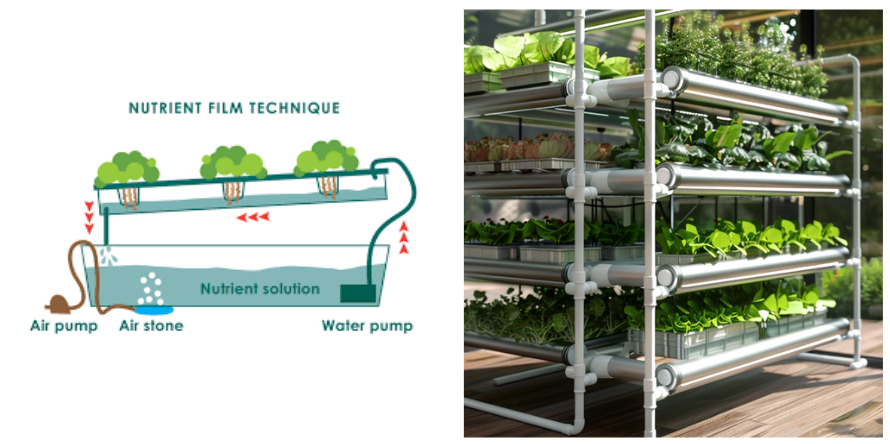

1. Nutrient Film Technique (NFT) Systems

The Nutrient Film Technique (NFT) stands out as a highly favored choice among commercial hydroponic systems, celebrated for its straightforward design and operational efficiency. In NFT setups, plants are nourished by a thin, continuous flow of water enriched with nutrients, which courses through inclined channels, ensuring that plant roots receive a steady stream of hydration and nourishment. This method is particularly effective for growing leafy greens, herbs, and other small vegetables that have less extensive root systems.

The design of NFT systems, with their gentle gradient, promotes efficient drainage and averts the risk of water stagnation, which is crucial for maintaining healthy root systems. Additionally, the consistent movement of the nutrient solution facilitates excellent aeration of the roots, which is vital for robust growth. Due to their simplicity, NFT systems are relatively easy to maintain and lend themselves well to automation, making them an attractive option for commercial growers who prioritize reliability and cost-effectiveness in their hydroponic endeavors.

Description of NFT Systems and How They Work

Nutrient Film Technique (NFT) systems are distinguished by their streamlined and effective configuration. Central to the NFT system is an array of grow channels, often made from food-safe plastic or similar impermeable materials, which are engineered with a gentle incline. This design is key to enabling a continuous, thin stream of a water solution, rich in nutrients, to flow smoothly.

The heart of the system is a reservoir that pumps this nutrient solution into the grow channels, allowing plant roots to bathe in this shallow, nutrient-laden stream. As the solution travels through the channels, it consistently delivers hydration, oxygen, and vital nutrients directly to the roots. A standout feature of the NFT system is its capacity to sustain high oxygen levels around the roots, which is essential for healthy plant growth. The minimal depth of the nutrient solution, combined with its unceasing flow, prevents the risk of root waterlogging, thus ensuring adequate oxygenation for respiration and efficient nutrient absorption.

The inclined nature of the grow channels is also vital for the system’s efficiency. After the nutrient solution has passed through the channels, it is collected at the end, then returned to the reservoir. Here, it is refreshed with nutrients as necessary and sent back into circulation. The potential for automation in NFT systems is significant, with the use of timers and sensors to regulate the flow of the nutrient solution and to keep a check on pH and nutrient concentration. This level of automation not only cuts down on manual labor but also promotes consistent, ideal conditions for plant growth.

Advantages and Disadvantages of NFT Systems

NFT systems are favored by many commercial hydroponic farmers for their numerous benefits:

- Water and Nutrient Efficiency: The recirculating setup of NFT systems reduces water waste and optimizes nutrient delivery to the plants.

- Space-Saving Design: The vertical arrangement and sloped channels of NFT systems enhance space efficiency, ideal for urban farming and locations with limited space.

- Low Maintenance: NFT systems are designed for ease, with automated nutrient delivery systems that lower the maintenance demands.

- Oxygenation: The continuous nutrient flow ensures high oxygen levels at the root zone, fostering robust plant growth.

On the flip side, NFT systems come with certain limitations:

- Limited Crop Variety: Best suited for plants with shallow roots like leafy greens and herbs, NFT systems are not optimal for larger plants with more extensive root systems.

- Power Dependency: The reliance on electric pumps for the nutrient solution’s flow means that NFT systems must have a consistent power supply.

- Susceptibility to Clogs: The narrow channels can become clogged, which can interrupt nutrient flow and harm the plants if not addressed promptly.

- Limited Buffer Capacity: With a shallow nutrient solution, NFT systems have a small buffer for pH or nutrient concentration changes, necessitating regular monitoring and adjustments.

Despite these drawbacks, the simplicity, efficiency, and effectiveness of NFT systems for certain crop types keep them as a prevalent choice among commercial hydroponic growers.

Top NFT System Recommendations for 2024

As we look towards 2024, the hydroponics industry is set to embrace several leading NFT systems known for their efficiency and sustainability. Among the top recommendations is the GrowStream NFT System, which is celebrated for its modular structure and scalability. It boasts food-safe channels and an intuitive control panel, catering to both professional and amateur growers.

Another prominent NFT system is the FarmTek NFT Channels. These channels offer an economical yet high-quality option, made from UV-resistant polypropylene, and are versatile enough to be incorporated into current hydroponic systems or to establish new ones.

For expansive commercial ventures, the Titan NFT System by Growlife stands out. It is designed to endure heavy usage and support dense plant growth. The system comes equipped with automated nutrient delivery and monitoring systems, ensuring that plants grow in the best possible conditions with minimal manual effort.

When selecting an NFT system for the year ahead, it’s critical to weigh aspects like scalability, automation capabilities, and how well the system will integrate with your current operations to guarantee smooth implementation and to optimize your crop yield.

2. Deep Water Culture (DWC) Systems

Deep Water Culture (DWC) systems, often referred to as reservoir systems, stand as a preferred option among commercial hydroponic farmers. In these systems, plants are held above a large reservoir that is filled with a nutrient-dense water solution. The roots dangle directly into this solution, where they are oxygenated by either an air stone or an air pump. This setup is especially advantageous for cultivating larger plants with significant root systems, including tomatoes, peppers, and cucumbers.

The uninterrupted access to both water and nutrients that DWC systems provide is conducive to swift plant growth and substantial yields, positioning DWC as a go-to for commercial growers aiming for peak production levels. Thanks to their straightforward design and minimal upkeep demands, DWC systems present a practical and effective approach for large-scale hydroponic farming.

Explanation of DWC Systems and Their Operation

Deep Water Culture (DWC) systems are lauded for their straightforward approach to maintaining a continuous supply of water, nutrients, and oxygen to plant roots. The foundation of a DWC system is a substantial reservoir made from food-safe plastic or another impermeable material, which is filled with a nutrient-enriched water solution. Plants are held aloft, with their roots immersed in this solution. To ensure the roots receive the necessary oxygen, an air stone or air pump is employed at the bottom of the reservoir to infuse the water with air.

DWC systems are particularly adept at accommodating larger plants with robust root systems, such as tomatoes, peppers, and cucumbers. The unceasing provision of water and nutrients is instrumental in fostering swift plant growth and abundant yields, which is why DWC systems are favored by commercial growers focused on optimizing productivity.

Operating a DWC system is relatively uncomplicated. The nutrient solution within the reservoir is replenished or changed out regularly to preserve the ideal nutrient concentration and pH levels. Moreover, it is critical that the air pump operates without interruption to guarantee sufficient oxygenation at the root zone. With the addition of timers, sensors, and monitoring systems, DWC setups can be automated, streamlining the control over nutrient application, water levels, and the growing environment. This level of automation not only diminishes labor demands but also promotes consistent and favorable conditions for plant development.

Pros and Cons of DWC Systems

Deep Water Culture (DWC) systems are celebrated for their numerous benefits, making them a go-to for many commercial hydroponic farmers:

- Simplicity: The uncomplicated nature of DWC systems allows for easy setup and maintenance, even for beginners in hydroponics.

- Rapid Growth: Continuous access to water, nutrients, and oxygen leads to swift plant development and substantial yields, ideal for commercial endeavors.

- Versatility: Capable of supporting a broad spectrum of plant types and sizes, DWC systems are suitable for everything from leafy greens to larger crops like tomatoes and peppers.

- Cost-Effectiveness: Due to their simple components and low upkeep, DWC systems are often more affordable than other hydroponic methods.

However, there are some considerations to keep in mind with DWC systems:

- Disease Susceptibility: The static water in the reservoir may become a breeding ground for pathogens and algae, posing a disease risk without proper care.

- Power Dependency: The necessity for continuous air supply from an air pump means DWC systems are at risk during power outages or equipment malfunctions.

- Limited Mobility: Once set up, moving or repositioning a DWC system can be difficult due to the weight of the water-filled reservoir.

- Temperature Regulation: Managing the water temperature in DWC systems can be challenging, particularly in extreme weather conditions.

Despite these challenges, DWC systems continue to be favored by commercial growers for their straightforward design, adaptability, and efficiency in fostering rapid plant growth and high yields. With diligent maintenance and monitoring, the drawbacks of DWC systems can be effectively managed.

Top DWC System Recommendations for 2024

Looking ahead to 2024, the hydroponics market is set to be led by several high-performing Deep Water Culture (DWC) systems. Among the top recommendations is the GrowStream DWC System, which is acclaimed for its robust build and ease of use. It comes equipped with a spacious reservoir, built-in air stones, and a modular grow tray, making it a versatile option for both commercial growers and enthusiasts.

Another notable DWC system is the FarmTek Deep Water Culture Kit. This kit is designed to be cost-efficient while maintaining high quality, providing all the essentials for a DWC operation, including a sturdy reservoir, air pump, and a flexible grow tray.

For operations on a grander scale, the Titan DWC System by Growlife is highly regarded. It features a strong construction that can support dense plant growth and includes automated systems for nutrient delivery and condition monitoring, ensuring that plants thrive with minimal manual effort.

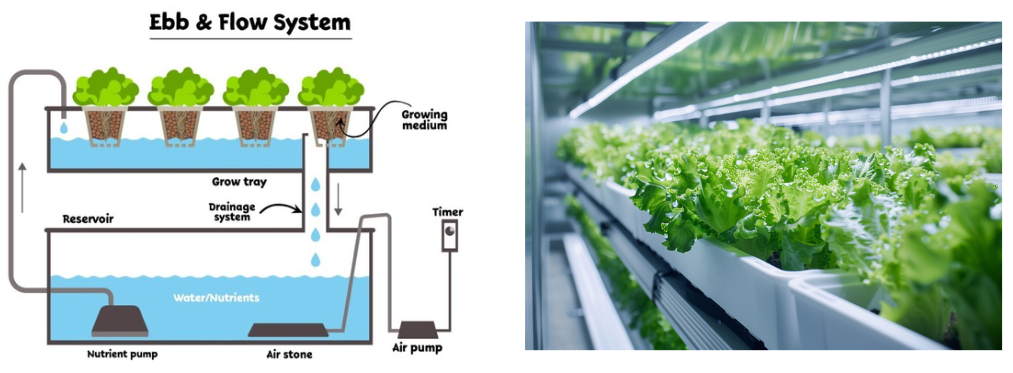

3. Ebb and Flow (Flood and Drain) Systems

Ebb and flow systems, commonly referred to as flood and drain systems, offer a dynamic and effective hydroponic solution for commercial growers. The principle behind these systems is to intermittently flood the grow beds with a nutrient solution from a central reservoir, which allows the plants to uptake essential moisture and nutrients. Following a predetermined interval, the solution is drained back into the reservoir. This action leaves the growing medium moist, yet oxygen-rich, which is crucial for healthy root development.

The ebb and flow method is characterized by its rhythmic watering cycle, which not only guarantees efficient nutrient distribution but also enhances root oxygenation. This system’s adaptability makes it suitable for cultivating a diverse array of crops, which is why it is widely adopted by commercial growers aiming for versatility and robust yields.

Description of Ebb and Flow Systems and Their Functionality

Ebb and flow systems, alternatively known as flood and drain systems, operate on a unique cycle of flooding and draining. Central to these systems is a reservoir brimming with a nutrient-dense water solution, paired with grow beds or trays filled with a medium like coco coir or perlite. The operation begins with the activation of a submersible pump, which propels the nutrient solution from the reservoir into the grow beds, immersing the plant roots in nutrient-rich water. This allows the plants to uptake essential moisture and nutrients.

Following a set duration, often between 15 to 30 minutes, the pump is turned off, prompting the nutrient solution to recede back into the reservoir. This action ensures the grow medium remains moist, yet oxygenated, creating an ideal environment for root health and growth. The repetitive nature of the ebb and flow process guarantees plants receive a balanced supply of water, nutrients, and oxygen, fostering robust growth and abundant yields.

With the integration of timers and sensors, ebb and flow systems can be fully automated, providing precise management over the flood and drain cycles. This adaptability makes ebb and flow systems a favored option for a broad spectrum of crops, including leafy greens, herbs, and larger fruit-bearing plants like tomatoes and peppers, offering commercial hydroponic growers both flexibility and operational efficiency.

Benefits and Drawbacks of Ebb and Flow Systems

Ebb and flow systems are highly regarded by commercial hydroponic growers for a multitude of reasons:

- Versatility: These systems are capable of supporting a diverse array of crops, from delicate leafy greens and herbs to robust fruiting plants, offering significant flexibility in crop production.

- Efficient Nutrient Delivery: The timed flooding and draining cycles provide plants with the precise amount of water and nutrients they need, enhancing growth while reducing waste.

- Oxygenation: As the grow medium is left well-aerated after each drain cycle, plant roots receive plenty of oxygen, which is crucial for healthy development.

- Scalability: The modular nature of ebb and flow systems allows for straightforward scaling, accommodating both small and extensive commercial operations with ease.

However, there are some considerations to be aware of with ebb and flow systems:

- Power Dependency: The reliance on pumps for the flood and drain cycles means that these systems are susceptible to power interruptions or equipment malfunctions.

- Risk of Waterlogging: Without precise management of the draining process, there is a risk of the grow medium becoming overly saturated, which can lead to root rot and other complications.

- Maintenance Needs: To prevent issues such as algae growth, pathogen accumulation, and mineral buildup, regular cleaning and maintenance of the system’s components are required.

- Initial Investment: Although ebb and flow systems are relatively straightforward, they may necessitate a larger initial investment compared to other hydroponic setups.

Despite these considerations, the advantages of ebb and flow systems, including their adaptability, effective nutrient delivery, and suitability for a broad range of crops, continue to make them a favored choice among commercial hydroponic farmers.

Top Ebb and Flow System Recommendations for 2024

With the hydroponics industry on the rise, several ebb and flow systems are set to lead the market in 2024 due to their efficiency and adaptability. A standout recommendation is the GrowStream Ebb and Flow System, celebrated for its modular structure and scalability. It comes equipped with sturdy grow trays, a dependable submersible pump, and an intuitive control panel, making it a prime choice for both commercial growers and enthusiasts.

Another notable system is the FarmTek Ebb and Flow Hydroponic Kit, which provides a budget-friendly option without sacrificing quality. This comprehensive kit contains everything needed for a full ebb and flow setup, including grow trays, a reservoir, and an adjustable flood tray.

For operations on a larger scale, the Titan Ebb and Flow System by Growlife emerges as a leading choice. Its heavy-duty construction is designed to support dense plant growth, and it features automated systems for nutrient delivery and condition monitoring, ensuring plants thrive with minimal manual oversight.

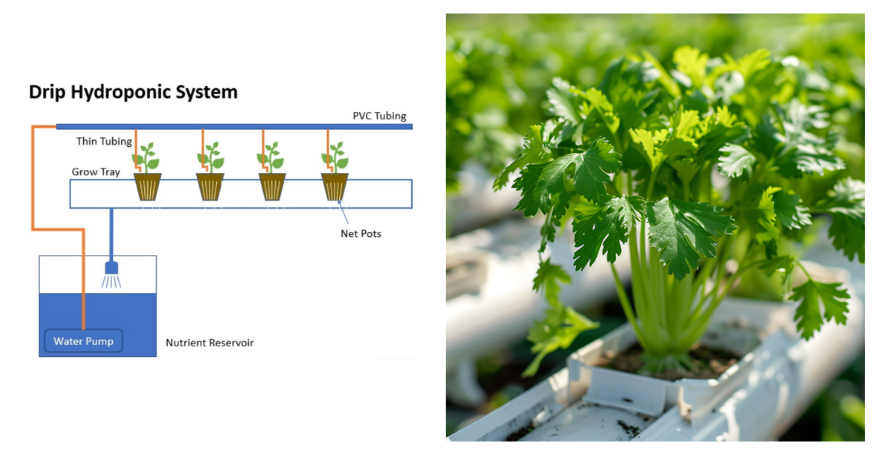

4. Drip Irrigation Systems

Drip irrigation systems stand out as an efficient method for water and nutrient delivery in commercial hydroponic farming. Utilizing a series of tubes and emitters, these systems deliver water and nutrients directly to the plant’s root zone in a slow, controlled manner. This precision not only enhances water and nutrient conservation but also helps in reducing the likelihood of diseases and pest problems by keeping plant leaves dry.

These systems are highly adaptable, compatible with a variety of growing mediums including soil, coco coir, and hydroton clay pebbles. This adaptability makes drip irrigation systems an excellent choice for a broad spectrum of crops and growing conditions. Offering significant water savings and targeted nutrient application, drip irrigation systems provide a sustainable and effective approach for managing commercial hydroponic gardens.

Overview of Drip Irrigation Systems and Their Working Principle

Drip irrigation systems are ingeniously crafted to supply water and nutrients with pinpoint accuracy directly to the plant’s root zone. Central to these systems is an intricate network of tubing and emitters, meticulously positioned at the base of each plant. The system operates by channeling a nutrient-enriched water solution from a reservoir through a primary supply line, which then divides into smaller drip lines. These lines are fitted with emitters, tiny devices designed to regulate and ensure a steady, slow release of the solution to the roots.

A standout feature of drip irrigation systems is their exceptional efficiency in water and nutrient conservation. By targeting the root zone directly, these systems drastically reduce evaporation and unnecessary runoff, offering substantial water savings over conventional irrigation methods. Furthermore, by keeping plant leaves dry, they significantly lower the risk of diseases and pest infestations, which are more prevalent under moist conditions. This not only enhances crop quality but also diminishes the reliance on chemical pesticides, aligning with sustainable and environmentally friendly agricultural practices.

The potential for automation in drip irrigation systems is considerable, with the integration of timers and sensors facilitating meticulous control over the delivery of water and nutrients. This tailored approach caters to the precise requirements of the crops, optimizing growth conditions while saving considerable time and labor.

Advantages and Disadvantages of Drip Irrigation Systems

Drip irrigation systems are highly favored by commercial hydroponic growers for their array of benefits:

- Water and Nutrient Efficiency: These systems deliver water and nutrients straight to the root zone, greatly reducing evaporation and runoff, which translates to considerable savings.

- Reduced Disease and Pest Risks: By keeping the foliage dry, drip systems lower the chances of disease and pest problems that are common in wetter environments.

- Versatility: They can be tailored to a variety of growing media and plant types, offering flexibility for different hydroponic applications.

- Automation and Precision: Drip systems can be automated with timers and sensors, providing exact control over the delivery of water and nutrients to meet the specific needs of each crop.

However, there are some challenges associated with drip irrigation systems:

- Clogging Issues: The emitters’ small openings can become blocked by mineral deposits or debris, necessitating routine maintenance and cleaning.

- Initial Setup Costs: Although they are cost-effective over time, the initial setup for drip systems may be more expensive than other hydroponic methods.

- Potential for Root Damage: If emitters are not installed or positioned correctly, they can cause harm to the roots or lead to uneven water distribution.

- Limited Mobility: Drip systems, once in place, can be difficult to move or adjust, particularly in large-scale commercial settings.

Despite these potential issues, the efficiency in water and nutrient use, the reduced risk of diseases and pests, and the adaptability to various crops and growing conditions keep drip irrigation systems in high regard among commercial hydroponic farmers.

Top Drip Irrigation System Recommendations for 2024

The hydroponics market is anticipating a surge in demand for water-efficient and precise irrigation solutions in 2024, with several top-notch drip irrigation systems leading the charge. A prime recommendation is the GrowStream Drip Irrigation Kit, which is celebrated for its straightforward setup and modifiable features. The kit comes complete with premium tubing, emitters, and a dependable submersible pump, making it a superb option for both commercial growers and gardening enthusiasts.

Another exceptional drip irrigation system is the FarmTek Drip Irrigation System, known for its affordability without sacrificing quality. It includes robust tubing, adjustable emitters, and an intuitive control panel that allows for meticulous water and nutrient management.

For expansive commercial ventures, the Titan Drip Irrigation System by Growlife stands out as a leading choice. It is designed for durability and can accommodate dense plant populations. The system also incorporates automated features for nutrient delivery and condition monitoring, ensuring plants receive the ideal care with minimal manual input.

5. Aeroponics Systems

Aeroponics systems represent the forefront of hydroponic farming, allowing plants to grow without any soil or solid medium. In these systems, plant roots hang in the air and are intermittently sprayed with a nutrient-dense water mist. This method is highly efficient in terms of water and nutrient use and encourages swift plant growth and abundant yields by ensuring the roots have access to ample oxygen.

Notably, aeroponics systems are designed to be compact, making them an ideal choice for urban farming initiatives and Controlled Environment Agriculture (CEA) setups. Despite necessitating a greater initial investment and a higher level of technical knowledge, aeroponics offers a sustainable and productive option for commercial growers aiming to optimize output in constrained spaces.

Explanation of Aeroponics Systems and How They Operate

Aeroponics systems offer a revolutionary method of hydroponic farming by enabling plant growth without the use of any solid substrate. In these systems, plant roots dangle freely in the air and are periodically coated with a fine mist of nutrient-rich water. The heart of an aeroponics setup is the grow chamber or tower, often made from materials such as plastic or polystyrene, which is both lightweight and durable. Plants are anchored within this chamber, leaving their roots in open air.

The system includes a reservoir filled with a nutrient solution that is linked to a pump connected to a series of misters or sprayers. When the pump is activated at set intervals, it delivers a mist that bathes the roots in nutrients and water. This process not only hydrates and nourishes the plants but also provides high levels of oxygen to the root zone, which is essential for vigorous growth and abundant yields.

Aeroponics systems are highly efficient in their use of water and nutrients, as the open-air root system minimizes waste, allowing the solution to be recirculated. With the addition of timers and sensors, these systems can be fully automated, offering precise management of misting schedules, nutrient concentrations, and the grow chamber’s climate. This level of automation minimizes the need for manual labor while maintaining consistent and ideal conditions for plant growth.

Pros and Cons of Aeroponics Systems

Aeroponics systems are celebrated for their numerous benefits in commercial hydroponic farming:

- Water and Nutrient Efficiency: Direct misting of the roots drastically reduces waste of water and nutrients, enhancing both conservation and sustainability.

- Rapid Growth and High Yields: Thanks to efficient nutrient delivery and optimal root oxygenation, aeroponics systems facilitate faster plant growth and larger yields.

- Space-Saving Design: The compact nature of aeroponics systems makes them ideal for urban farming and Controlled Environment Agriculture (CEA) setups.

- Reduced Disease Risks: The lack of a growing medium and the airy environment significantly lower the chances of soil-borne diseases and pests.

However, there are challenges to consider with aeroponics systems:

- High Initial Costs: The setup of an aeroponics system demands a substantial upfront investment in specialized equipment and infrastructure.

- Technical Expertise Required: A higher level of technical knowledge is necessary for the operation and maintenance of aeroponics systems compared to other hydroponic methods.

- Power Dependency: The reliance on continuous electricity to power pumps and misters makes aeroponics systems susceptible to power interruptions or equipment failures.

- Limited Crop Variety: Although versatile, aeroponics systems might not be the best fit for plants with large root systems or those that require specific types of growing media.

Despite these considerations, the efficiency in resource use, the potential for high yields, and the reduced risk of diseases make aeroponics systems a favored option among commercial growers looking to optimize production in constrained spaces.

Top Aeroponics System Recommendations for 2024

The hydroponics industry is set to embrace several leading aeroponics systems in 2024, catering to the growing need for systems that are both space-efficient and yield-enhancing. A top recommendation is the GrowStream Aeroponics System, celebrated for its modular structure and scalability. It comes equipped with a sturdy grow chamber, high-performance misters, and an intuitive control panel, making it a versatile choice for growers of all levels.

Another notable system is the FarmTek Aeroponic Growing System, known for its affordability without sacrificing quality. It features a durable grow chamber, a dependable nutrient delivery system, and adjustable controls for the growing environment, offering a comprehensive solution for efficient plant growth.

For operations on a larger scale, the Titan Aeroponics System by Growlife stands out. Its heavy-duty construction is designed to accommodate dense plant growth, and it includes advanced features for automated nutrient delivery and condition monitoring, ensuring plants thrive with minimal manual effort.

Factors to Consider When Choosing a Commercial Hydroponic System

Choosing the appropriate commercial hydroponic system is a pivotal decision that can significantly impact yields, resource efficiency, and the overall success of your operation. When navigating the diverse options available, it’s important to consider a variety of critical factors tailored to your specific needs and objectives. These factors encompass the spatial and layout limitations of your growing area, the particular types of crops you intend to grow, their respective growth cycles, and their unique nutrient requirements.

Furthermore, it’s vital to assess the initial investment and the ongoing operational costs, the simplicity or complexity of system maintenance and the possibility of integrating automation. Scalability and the capacity for future expansion are also crucial considerations, ensuring that your hydroponic system can adapt and grow with your business, contributing to a sustainable and profitable venture.

Space and Layout Requirements

The dimensions and configuration of your cultivation space are critical in choosing an appropriate commercial hydroponic system. Systems like the Nutrient Film Technique (NFT) and aeroponics are engineered for vertical or stacked setups, which are excellent for optimizing space in urban farms or Controlled Environment Agriculture (CEA) facilities. Conversely, Deep Water Culture (DWC) and ebb and flow systems tend to spread out more horizontally, necessitating ample floor space to accommodate their extensive reservoirs and grow beds.

It’s imperative to measure the available area, taking into account factors such as ceiling height, to ensure the hydroponic system fits well. The layout should also promote easy access for maintenance and harvesting activities. Systems that demand regular attention may benefit from a layout that allows for ease of movement, whereas those that are more automated and require less hands-on work can afford to be arranged in a tighter, more space-efficient manner. A thorough assessment of your space and layout will guide you to a hydroponic system that not only optimizes your available area but also supports effective and streamlined operations and maintenance routines.

Crop Type and Growth Cycle

The selection of a commercial hydroponic system should be closely aligned with the specific crops you intend to grow and their growth cycles. Each system has its strengths in supporting different types of crops, which vary in root structure, nutrient uptake, and overall growth patterns. For example, the Nutrient Film Technique (NFT) is particularly well-suited for crops with shallow root systems, such as leafy greens and herbs. In contrast, Deep Water Culture (DWC) systems are more accommodating for larger plants with more substantial root systems, including tomatoes and peppers. Aeroponics systems might not be the best fit for crops with very dense or expansive root systems.

Furthermore, the growth cycle length of your crops will dictate the frequency of harvests and the necessity for system maintenance or modifications. Crops with rapid turnover might necessitate more regular harvesting and cleaning of the system, whereas crops with longer growth periods could be more compatible with systems that offer advanced automation and monitoring features. By taking into account both the type of crops and their respective growth cycles, you can choose a hydroponic system that not only caters to the needs of your plants but also fits your operational workflow and production ambitions.

Initial and Ongoing Costs

In the process of choosing a commercial hydroponic system, a thorough analysis of both the initial investment and the recurring operational expenses is essential. Systems with a steeper initial price tag might ultimately lead to cost savings due to their efficiency, reduced consumption of resources, or lower upkeep needs. It’s important to assess the expenses related to the components of the system, including grow beds, reservoirs, pumps, and any automation technology.

Consideration should also be given to the costs of growing mediums, nutrient solutions, and potential modifications or enhancements to your infrastructure. Recurring expenses will include the energy used by pumps, lighting, and climate control systems, as well as labor for system maintenance, harvesting, and monitoring. Systems that boast advanced automation and monitoring may come with a higher upfront cost but could offer savings in labor costs over time.

Additionally, the potential return on investment (ROI) should be evaluated, taking into account the system’s capacity to increase profits through higher yields, enhanced crop quality, or decreased use of resources. By carefully balancing the upfront and ongoing costs with the anticipated benefits, you can select a hydroponic system that fits your financial plan and supports your profitability objectives in the long run.

Ease of Maintenance and Automation

The maintenance requirements and automation capabilities of a commercial hydroponic system play a crucial role in determining its operational efficiency and profitability. Systems that demand regular manual input or have complicated upkeep routines can significantly increase labor costs and reduce overall productivity. Conversely, systems equipped with advanced automation and monitoring technologies can enhance operational efficiency, lower labor demands, and promote consistent, ideal growing conditions.

When selecting a system, it’s beneficial to look for features such as automated nutrient delivery, pH and EC (Electrical Conductivity) monitoring, and controls for managing temperature, humidity, and lighting. The design and accessibility of the system for routine maintenance tasks, including cleaning, replacing parts, and harvesting, are also important considerations. Systems designed with modularity or components that are easy to disassemble can greatly simplify maintenance procedures and minimize operational downtime.

Opting for a hydroponic system that emphasizes ease of maintenance and robust automation can lead to significant savings in labor costs, enhanced efficiency in resource use, and steady crop quality and yields. This approach not only boosts the profitability of your hydroponic venture but also frees up resources to invest in other areas of your business, contributing to its overall growth and success.

Scalability and Expansion Potential

The scalability and potential for expansion of your hydroponic system are critical considerations as your commercial operation grows. Certain hydroponic systems offer greater scalability, facilitating the addition of new components or modules without major disruptions. For instance, modular systems like the Nutrient Film Technique (NFT) or ebb and flow setups can be expanded with relative ease by incorporating additional growing channels or trays.

Drip irrigation systems also lend themselves to scaling, as the network of tubing and emitters can be extended to support a larger number of plants. In contrast, systems such as Deep Water Culture (DWC) or aeroponics might present more challenges when scaling up due to the need for more significant infrastructure changes or complete system overhauls.

When choosing a hydroponic system, it’s important to not only consider your immediate production requirements but also to plan for future growth. Opting for a system with high scalability can prevent the need for a complete system replacement as your operation expands, allowing for a more efficient transition and reduced downtime.

Conclusion

In the dynamic realm of commercial hydroponic farming, the choice of the right system is a critical factor in optimizing yields, conserving resources, and securing long-term financial success. Each hydroponic method, from the well-established Nutrient Film Technique to the advanced aeroponics, presents distinct benefits and considerations that align with particular types of crops, spatial limitations, and operational goals.

A thorough assessment of various factors — including the available space and layout, the types of crops and their growth cycles, initial and ongoing costs, maintenance and automation requirements, and the potential for scalability — is essential for making a well-informed decision that supports your objectives. By integrating the latest technological advancements with a clear understanding of your unique needs, you can harness the full capabilities of commercial hydroponic systems and pave the way for a thriving and sustainable agricultural enterprise.

Summary of the Top Commercial Hydroponic Systems for 2024

Looking forward to 2024, the landscape of commercial hydroponic farming is set to be dominated by several standout systems, each offering unique benefits to cater to the diverse needs of growers. The Nutrient Film Technique (NFT) systems, highlighted by the GrowStream NFT System and FarmTek NFT Channels, are celebrated for their simplicity and adaptability, making them particularly suited for cultivating leafy greens and herbs.

Deep Water Culture (DWC) systems, including the GrowStream DWC System and the Titan DWC System from Growlife, are preferred for growing larger plants with significant root systems, as they facilitate swift growth and impressive yields. Ebb and flow systems, such as the GrowStream Ebb and Flow System and the FarmTek Ebb and Flow Hydroponic Kit, stand out for their versatility and efficient nutrient delivery.

For those prioritizing water efficiency and precise nutrient application, drip irrigation systems like the GrowStream Drip Irrigation Kit and the FarmTek Drip Irrigation System offer an optimal solution, also minimizing disease risks. Lastly, aeroponics systems, with the GrowStream Aeroponics System and the Titan Aeroponics System from Growlife leading the charge, present a space-efficient and highly productive option, ideal for urban farming and controlled environment agriculture (CEA) settings.

Importance of Proper System Selection for Maximizing Yield and Profitability

Choosing the right commercial hydroponic system is a pivotal decision that directly influences your operation’s yield, efficiency in resource use, and overall profitability. Given the diverse range of systems available, each designed with particular crop needs, spatial limitations, and operational demands in mind, a thorough evaluation of your specific requirements and objectives is crucial. Selecting an optimal hydroponic system can lead to enhanced resource management, reduced waste, and the creation of an optimal environment for crop growth, thereby increasing yields and improving the quality of your produce. This enhancement in production not only boosts revenue but also strengthens your position in the competitive market.

Moreover, an aptly chosen system can simplify operational processes, diminish labor costs through automation, and facilitate efficient maintenance practices. It also provides the flexibility needed to scale operations in line with future growth and evolving market trends. Aligning your choice of hydroponic system with your overarching business goals is essential for fostering a sustainable and profitable venture, capable of navigating the dynamic landscape of commercial hydroponics. Devoting the necessary time and resources to carefully select the most fitting commercial hydroponic system is a fundamental step towards unlocking maximum yield potential, ensuring resource efficiency, and securing long-term success in the competitive arena of commercial hydroponic farming.